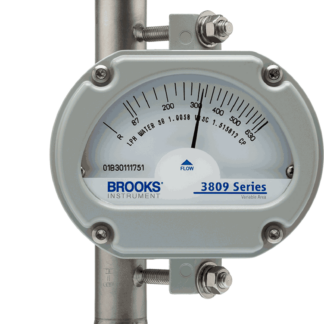

Description

2500 Series Acrylic Tube Custom Variable Area Flow Meters

Start with precision machining. Add customized options. Make your very own Custom Plastic Rotameter.

For applications where measuring air, water or gas flow requires non-standard features, our 2500 Series Custom Solutions gives you three levels of customization and price points to meet your specific project or OEM requirements.

The 2500 Series Custom Solutions start with the same precision-machined, unibody, acrylic construction used in our standard 2500 Series design. Then you can choose from a range of customization options – changing basic features like scale and logo and even physical attributes like body shape and inlet/outlet orientation.

Features

- Precision-drilled acrylic uni-body

- Measure flow rates from 4 ccm to 20 GPM water and from 40 ccm to 4000 LPM air

- Three accuracy levels, from 2% to 5% full scale, depending on model

Level 1 customization options include:

- Custom scale (for standard ranges) and logo

- Custom backing (clear, printed white, or printed one or more colors)

- Pressure compensated scale

- Choice of fittings or no fittings

- Non-standard mounting holes (bushings)

Level 2 customization includes Level 1 options, plus:

- Custom ranges (includes custom scales)

- Standard valve on outlet

- Custom valve stem or knob on inlet or outlet

- Non-standard threads

- Non-standard fittings (choice of materials and sizes)

- Beveled edges or faces

Level 3 customization includes any Level 1 and 2 options, plus:

- More than one tube, float or scale (mixing, inlet or outlet manifolds)

- Cylindrical body (any length, material or diameter)

- Rectangular body (different dimensions that standard 2500 Series stock)

- Special inlet and outlet orientations and machining operations

- Special features, such as lighted scale or glass tube insert